Shimadzu Nexera Gel Permeation Chromatography (GPC) System provides highly reliable and highly expandable performance in a wide variety of applications. Hardware with fast instrument stabilization and excellent reproducibility of analytical results, and software with analytical workflow automation and overlapping injection functions and a user-friendly analysis screen view contribute to increasing productivity.

In addition, the Analytical Intelligence function based on state-of-the-art digital technology ensures highly reliable analytical results, preventing potential problems with Gel Filtration Chromatography and ensuring that the instrument is always in a stable state, regardless of the analyst's skill, knowledge or experience level. .

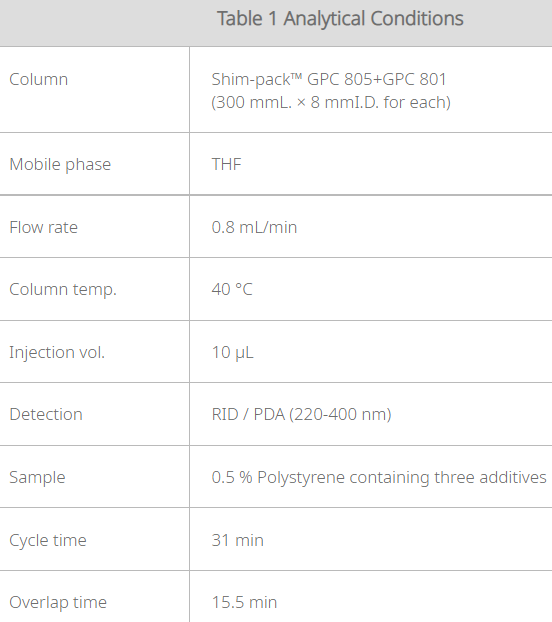

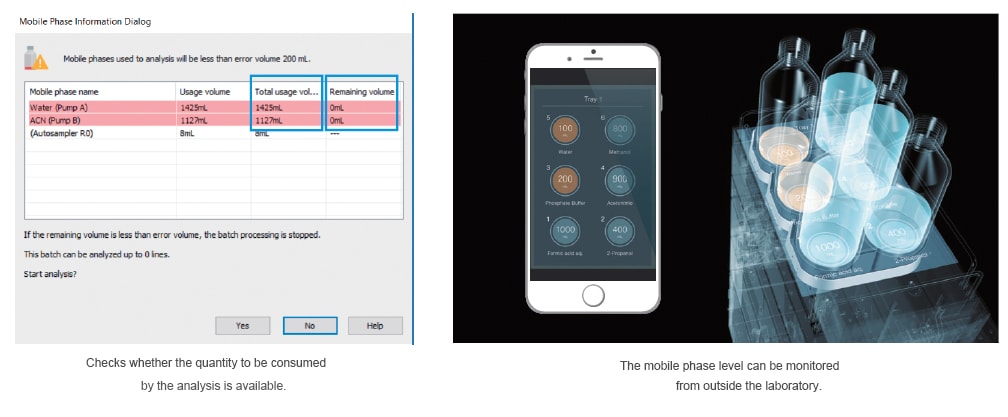

Reservoir tray weight sensors (optional) can be used to monitor the volume of mobile phase or autosampler rinse solution in up to twelve containers. The containers can also be checked remotely from a smart device. You will no longer need to worry about running out of mobile phase mid-analysis, because the device will notify you before starting the run if the volume remaining is too low.

In rare cases, air bubbles can form in the mobile phase and cause problems if inhaled into the pump. The Nexera has the ability to monitor baseline changes and pressure fluctuations to check for abnormalities. When it detects an unusual fluctuation, it can automatically pause the analysis, purge the flow path, and restart analysis once it has confirmed recovery to normal pressure.

Functionality for assisting the entire series of analytical process steps, from instrument startup to shutdown, significantly increases work efficiency. FlowPilot mobile phase flowrate control functionality is linked to column oven temperature, so that columns are protected during automatic column equilibration. By automatically checking for baseline drift, instrument stability is maintained without the operator having to remain next to the instrument.

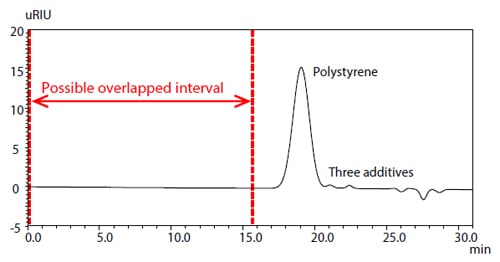

Measuring molecular weight distribution of polymer compound by size exclusion mode is one of the typical parts of HPLC and generally called gel permeation chromatography (GPC). Nowadays there is an increasing demand demand for high throughput analysis even in well-established GPC. Here we introduce a novel GPC analysis that affords both high throughput GPC results by overlapped injection using conventional size of columns and simultaneous determination of polymer additives.

A refractive index detector (RID) that gives a response to a sample weight is commonly employed for GPC to calculate average molecular weight and polydispersity. On the other hand, A UV detector is used for determination of polymer additives such as antioxidants. Consequently, serially connected those two detectors were used for this study. In GPC, there is hardly any eluates prior to exclusion limit. So if the sample elution band from previous injection is managed to be overlapped within this no elution interval in present analysis, short analysis cycle time can be obtained and it provides increased throughput in sequential analyses. When two or more polymer additives are contained, correct determination of those small additives is difficult because complete separation of additives is almost impossible even using GPC columns of small exclusion limit due to small difference of molecular weight among those polymer additives. To address this difficulty, a photodiode array detector (PDA) that affords spectrometric information as well as chromatographic results was employed to give increased separation of polymer additives by peak deconvolution function within a single GPC analysis.

The visual and table in the figure show the obtained chromatogram of the polystyrene containing three antioxidants and the analytical conditions used, respectively.