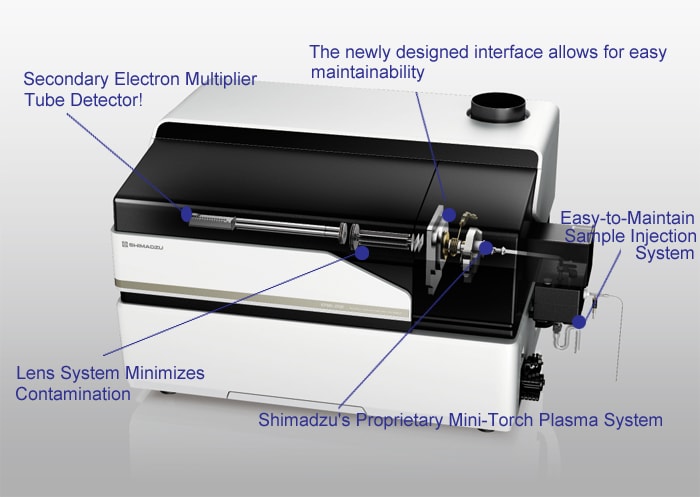

With its newly developed collision cell and optimized internal structure, the ICPMS-2030 Inductively Coupled Plasma Mass Spectrometer with its superior sensitivity, the adoption of the proprietary mini torch unit and the provision of Eco mode, greatly reduce the amount of argon gas needed for analysis to the lowest levels in the industry.

As a result, low operating costs are guaranteed.

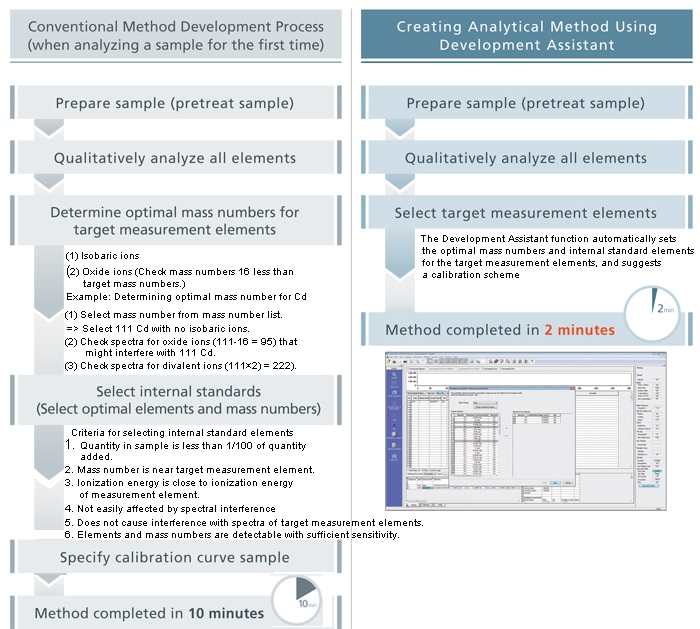

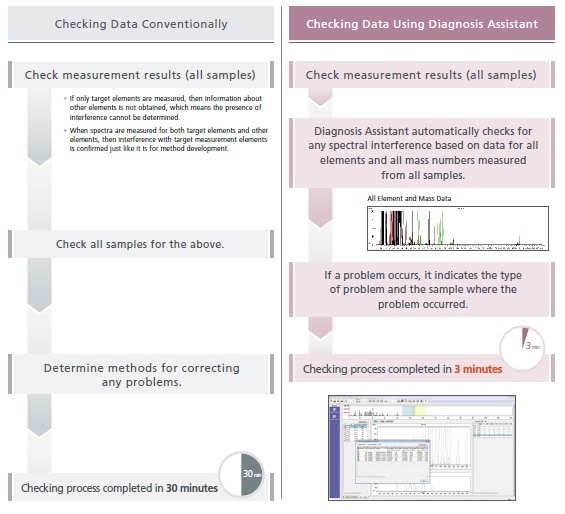

The Software Development Assistant function automatically adjusts the optimal analysis conditions for quantitative analysis. Then, after the measurements are complete, the Diagnostic Assistant function automatically checks the validity of the required data. While the burden on the user is reduced, the efficiency of the analysis and the reliability of the data are increased. Complies with FDA 21 CFR PArt 11.

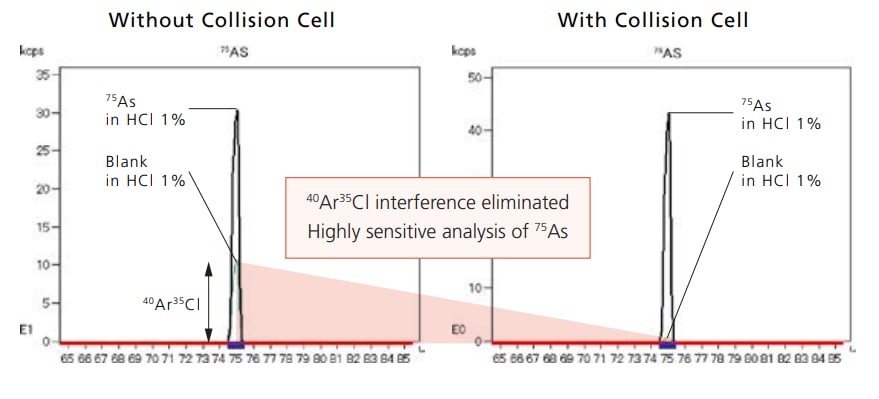

With this newly developed collision cell, polyatomic ions that previously may have been detected as spectral interference are efficiently eliminated by helium gas flowing through the cell, allowing the high-sensitivity analysis.

If chlorine is in the sample when performing quantitative analysis of 75As, 40Ar and 35Cl combine to form 40Ar35Cl, which overlaps the mass number of As, creating interference.

The collision cell eliminates the spectral interference from Cl, enabling the highly sensitive measurement of As.

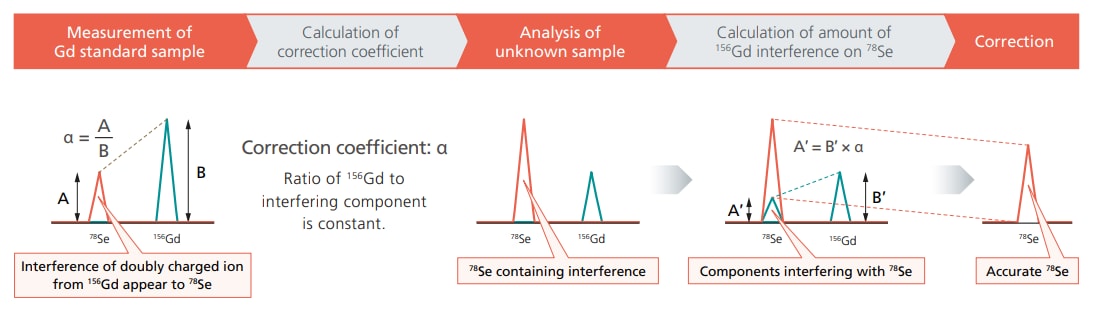

Shimadzu's proprietary On-Line IEC (Inter Element Correction) provides correction for spectral interference that could not be eliminated with the collision cell. Since the interference correction coefficient can be acquired only by a single measurement of a standard sample of the interfering element, the correction can be simply and accurately made. There's no need for complicated assessments of conditions, as with reaction cell technology.

If 156Gd is in the sample when performing quantitative analysis of 78Se, spectral interference will occur with respect to 78Se. By measuring a standard sample of Gd, the correction coefficient can be obtained. Then, the portion where interference occurs can be corrected when measuring the unknown sample, and the accurate quantitation of 78Se can be accomplished.

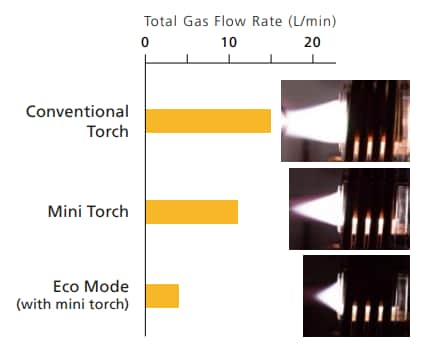

One of the highest costs associated with ICP-MS systems is the large quantity of argon gas they consume. However, Shimadzu's proprietary mini-torch plasma system consumes 2/3 the argon gas (11 L/min) as conventional plasma torches. Consequently, one gas cylinder of argon (~7,800 liters) allows for approximately ten hours of continuous operation.

During standby when Eco mode is active, the plasma gas flow and power are reduced to 5 L/min and 0.5 kW to minimize the required gas and electricity; however, analysis can be started immediately with no loss of productivity

High-purity argon gas required by conventional systems is no longer necessary. Using less expensive argon gas (99.95%) can reduce costs.

Shimadzu is the world's first ICP manufacturer to develop an all-solid-state high-frequency power supply. Due to Shimadzu's extensive experience, this free-running type high-frequency power supply unit offers the highest output stability.

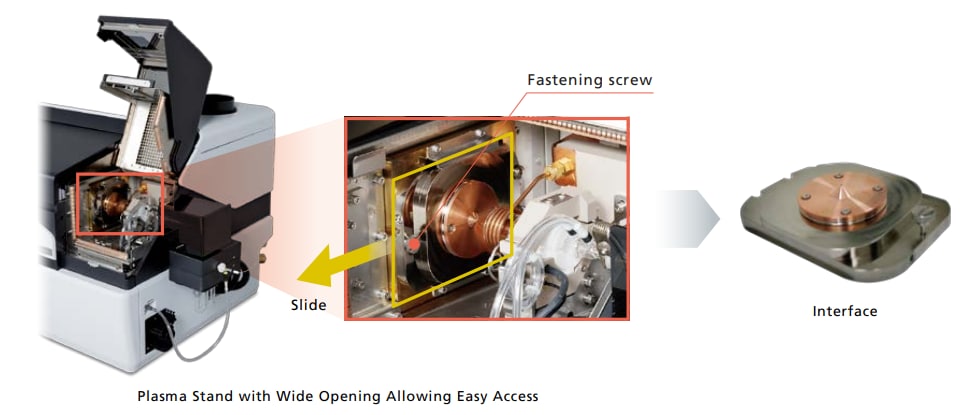

The smaller three-stage split-flow turbomolecular pump is especially easy to maintain, maximizing up-time of the instrument.

The 9-digit dynamic range detector allows for measuring major components and trace components simultaneously with high sensitivity.