Analyzing moisture and how much is critical to the performance of petroleum products as well as infrastructure and product integrity. For example, moisture in petrochemical raw materials can cause freezing of pipelines and valves, as well as poisoning some catalysts.

In moisture analysis, with the method offered by Shimadzu, the proprietary Barrier Discharge Ionization Detector (BID) is combined with MilliporeSigma's* moisture analysis column "Watercol". This combination separates and measures moisture in a feedstock formulation and provides precise and accurate results with measurements down to the ppm moisture detection level without intervention.

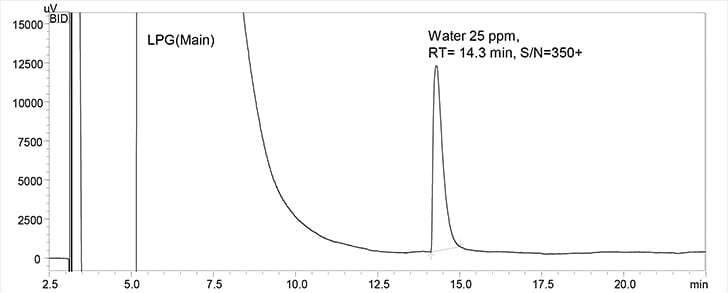

Unlike traditional wet chemistry methods, this new method uses Gas Chromatography (GC) with a newer detector, the Barrier Discharge Ionization Detector (BID). BID is a highly sensitive device that creates ionization from a Helium-based, dielectric barrier discharge plasma. A 17.7 eV plasma is produced by applying a high voltage to a quartz dielectric chamber in the presence of helium at a relatively low temperature. Compounds leaving the GC column are ionized by this He plasma energy and then detected by the collecting electrode and processed as peaks.

BID is more sensitive than both a Thermal Conductivity Detector (TCD) and a Flame Ionization Detector (FID) and is capable of analyzing down to water levels below ppm. In addition, the method uses MilliporeSigma's new, highly polar ionic liquid column Watercol™, which provides excellent water retention, separation and peak shapes.

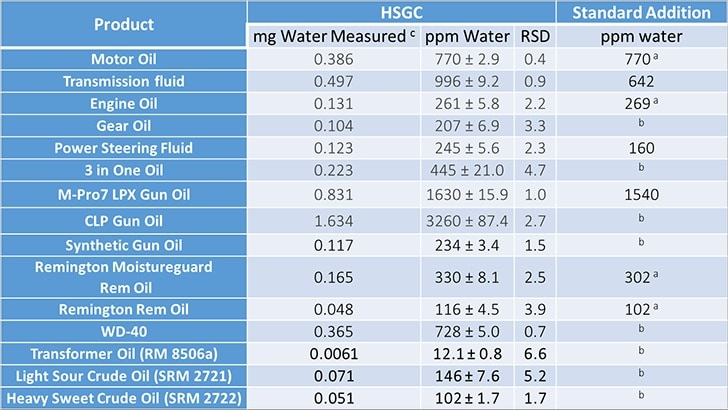

Many different types of samples can benefit from analyzing moisture content via the GC/BID Watercol™. Excellent precision and accuracy are achieved using manual or automated systems. Depending on the types of samples, a liquid/gas sampling valve can be used to introduce the samples to the GC or the Shimadzu HS-20 NX Headspace Sampler.

* MilliporeSigma, the life science business of Merck KGaA

Watercol is a trademark of MilliporeSigma.